Sebago Brewing Co. in Maine, USA, recently installed a DALUM CO2 Recovery Plant and is now able to recover their own CO2 from fermentation, thus lowering their carbon footprint and strengthens their resilience against CO2 supply disruptions.

Cheers to the Sebago team!

In a world where sustainability and environmental consciousness are increasingly becoming not just buzzwords but crucial practices, Sebago Brewing Co. has taken a bold and innovative step forward. The Maine-based craft brewery recently installed a DALUM CO2 Recovery Plant at its Gorham facility, joining the growing movement of breweries finding solutions to reduce their carbon footprint while ensuring the steady flow of their beloved craft beers.

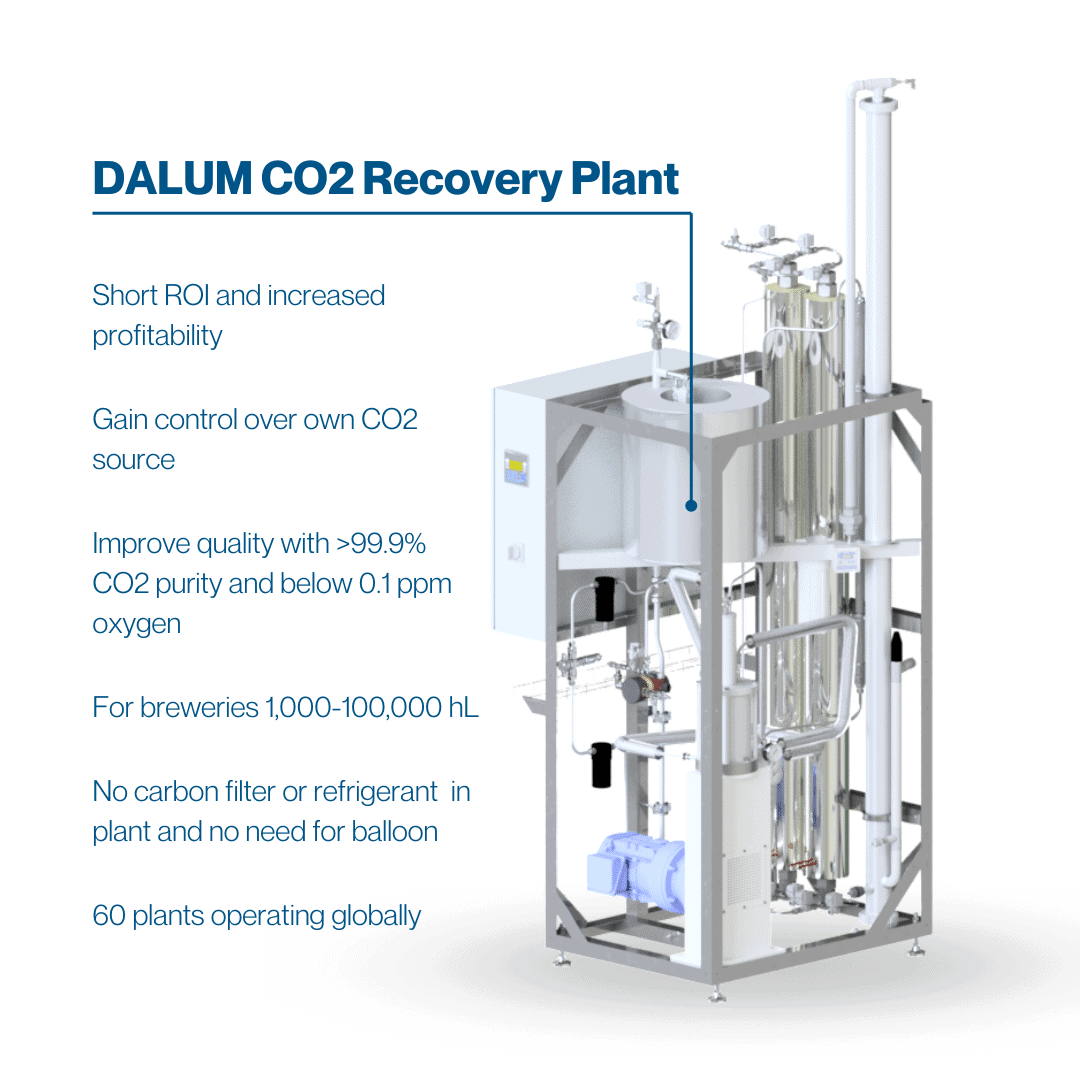

Sebago Brewing Co., founded in 1998 and known for its locally sourced, high-quality brews, is now making waves for its commitment to sustainability. In a move that directly addresses the potential risks of CO2 shortages—a problem that has already rattled the beer industry in recent years—Sebago has installed a cutting-edge CO2 recovery system, designed by Denmark-based DALUM Beverage Equipment.

For those unfamiliar, CO2 is a vital component in the brewing process. It’s not only produced during fermentation, but it’s also used to carbonate beer. In recent years, CO2 shortages have driven prices up and left breweries scrambling. But rather than being held hostage to market fluctuations, Sebago is taking control of its supply chain and environmental impact by capturing and recycling the CO2 produced during fermentation.

The DALUM CO2 recovery system is engineered to capture between 70% and 80% of the CO2 generated during fermentation. Once captured, the CO2 is purified, liquefied, and then reused in the brewing process. According to Chet Kiedrowski, who oversees DALUM’s U.S. operations, Sebago’s new system will save 128,000 pounds of CO2 annually from being released into the atmosphere. To put that into perspective, it’s equivalent to the emissions from burning over 6,500 gallons of gasoline—no small feat in the fight against climate change.

This system doesn’t just offer environmental benefits. It also offers Sebago an economic edge by reducing reliance on external CO2 suppliers and the uncertainty that comes with fluctuating market prices. Additionally, this technology could set a precedent in the craft beer industry, especially for other small-to-mid-sized breweries that, until now, haven’t had access to such scalable solutions.

Sebago co-founder Kai Adams underscored the importance of this technology, saying, “Collecting and reusing CO2 that brewers produce seems obvious, but it’s taken recent advances in recapture technology and market demand to help scale equipment to work at breweries our size.” Adams and his team have been contending with CO2 supply chain issues for some time, and this solution feels both practical and forward-thinking.

For Sebago Brewing, this investment aligns with their broader commitment to sustainability. As a company rooted in Maine’s natural beauty, Sebago has long been an advocate for practices that protect the environment. From sourcing local ingredients to supporting community initiatives, the brewery has built its reputation on being a responsible steward of the resources it uses.

Peter Dahlen, Sebago’s Director of Brewing Operations, emphasized the broader vision: “This new system will help us connect our CO2 generation-and-use cycle to eliminate waste. We’re really excited to implement this sustainable advancement in our facility and hope to see other brewers be able to apply it to theirs as well.”

This eco-conscious investment in CO2 recovery is just the latest example of how Sebago Brewing is stepping up to the sustainability plate. Their efforts are part of a larger trend within the craft beer industry, where brewers are increasingly looking for ways to reduce waste, cut energy use, and minimize their environmental footprint without sacrificing quality or flavor.

While Sebago is currently the first brewery in Maine to install a DALUM CO2 recovery system, they’re likely to be trailblazers for others to follow. The craft beer industry, often hailed for its innovation and creativity, is ripe for more sustainable practices that not only benefit the environment but also provide economic stability for brewers. Sebago’s leadership shows that thinking green doesn’t just make environmental sense—it makes business sense too.

For beer lovers, it’s a win-win. They can continue to enjoy Sebago’s signature brews—now knowing that every sip is a bit more sustainable. Whether you’re sipping a Sebago Frye’s Leap IPA or their Saddleback Mountain Brown Ale, you’re not just tasting great beer; you’re supporting a brewery that’s making a real difference.

Sebago’s adoption of the DALUM CO2 Recovery Plant marks a significant step forward in brewing technology and sustainability. As craft brewers continue to innovate and respond to both environmental and economic challenges, the future of beer is looking not only delicious but also more sustainable.

For the Maine community, Sebago’s commitment to sustainability reflects the values of local businesses working to protect the environment and support their communities. As more breweries across the country take note, Sebago Brewing is helping set the standard for what responsible craft brewing can look like in the 21st century.

© 2024 Dalum Equipment