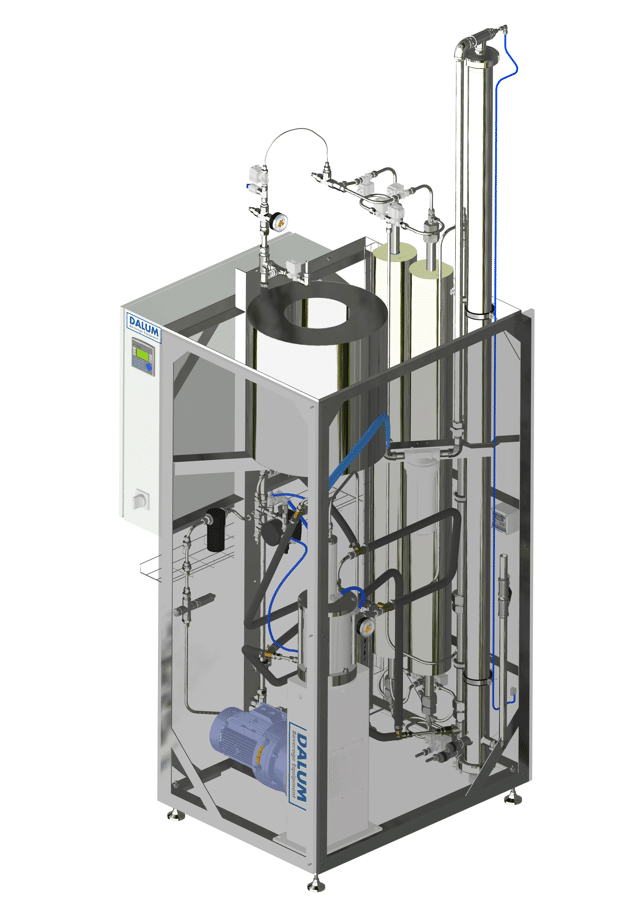

The Mini is our initial model of CO2 recovery Plants, featuring a DALUM compressor with a theoretical compressor displacement of 10 kg/hr and an LCO2 output of 8 kg/hr.

Capacity : The Mini model is specifically designed for breweries with a production ranging between 5,000 – 15,000hl/yr, assuming an alcohol content of 5%.

| TECHNICAL DATA | |

|---|---|

| Model | Mini |

| Capacity | Theoretical compressor displacement 0-10 kg CO2 feed gas per hour. Estimated liquid output 0-9 kg CO2 per hour. |

| Purity | 99.980%-99.995% CO2 purity depending on feed. |

| CO2 supply pressure | Minimum 0.2 bar from fermenter. |

| Feed gas purity | Minimum 96% CO2, maximum 0.6% oxygen (incondensable gas). |

| Room temperature | Minimum 5°C and maximum 40°C. |

| UTILITY DATA | |

|---|---|

| Electricity | 3x400V +N+P, 50 Hz, 10 Amps fuses. |

| Cooling media | -5 to 0°C, flow 0-15 L/min or max 1.0 kW (0.3 kW compressor) Delta T minimum 1.5 bar. No calcium or oil in cooling source. |

| Water | 0-15 L/hour. |

| Drainage | 0-15 L/hour. |

| FEATURES | |

|---|---|

| Dimensions | LxWxH: 1x1x3 meters and 1x2x3 including foam trap. |

| Noise level | App. 65 dB(A). |

| Materials | Stainless steel (exclusive motor, gearboxes, control cabinet) and selected electrical valves in brass. |

| Controls | PLC w/ colour touchscreen and fully automatic operation. Remote access to live dashboard from pc and smartphones. |

| Components | As per DALUM's best choice. |

| Covers | Optional – recommended if module is placed in fermentation area with spraying water and cleaning agents. |

| PED-code | The CO2 module is outside PED and ASME regulation for site inspection. No approval needed. |

| Documentation | The equipment is delivered CE marked and with available online manuals, videos and documentation for use and maintenance. |

© 2024 Dalum Equipment